The importance of jigs and fixtures :

Whether it’s jigs, fixtures or grips, tooling remains a vital, if seemingly mundane, part of the manufacturing process. Regardless of the complexity of your products, the productivity and efficiency of your production depends on the availability of high-quality tooling aids.

Maximising production efficiency and productivity is a key concern for manufacturers. Jigs and fixtures are manufacturing aids used to increase the reliability, accuracy and quality of the manufacturing process whilst minimising production cycle times and improving worker safety.

Fundamentally, the purpose of jigs, fixtures and manufacturing aids is to provide an accurate, repeatable and interchangeable manufacturing process whilst reducing production time and human error.

Whether it’s jigs, fixtures or grips, tooling remains a vital, if seemingly mundane, part of the manufacturing process. Regardless of the complexity of your products, the productivity and efficiency of your production depends on the availability of high-quality tooling aids.

Maximising production efficiency and productivity is a key concern for manufacturers. Jigs and fixtures are manufacturing aids used to increase the reliability, accuracy and quality of the manufacturing process whilst minimising production cycle times and improving worker safety.

Fundamentally, the purpose of jigs, fixtures and manufacturing aids is to provide an accurate, repeatable and interchangeable manufacturing process whilst reducing production time and human error.

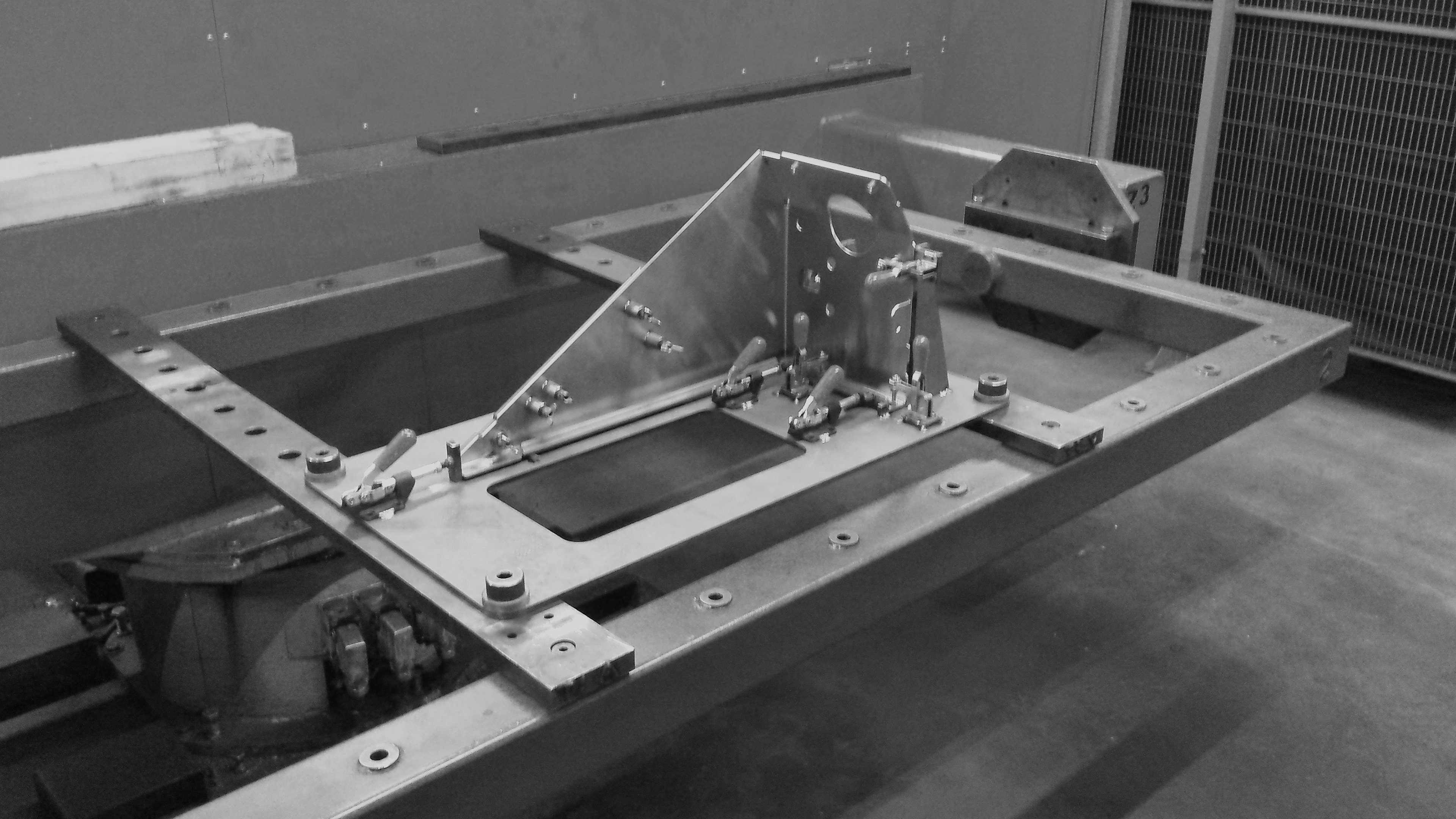

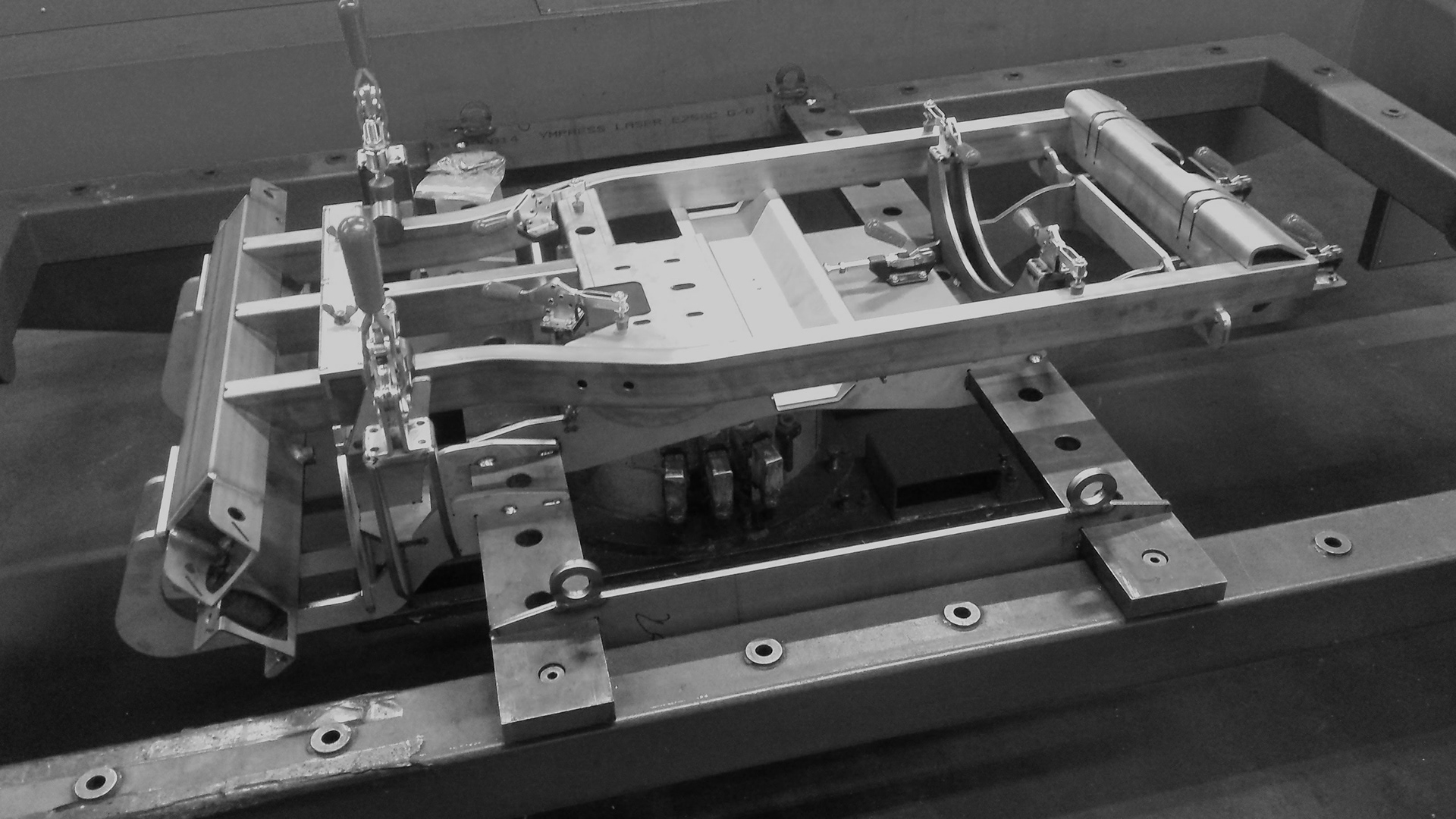

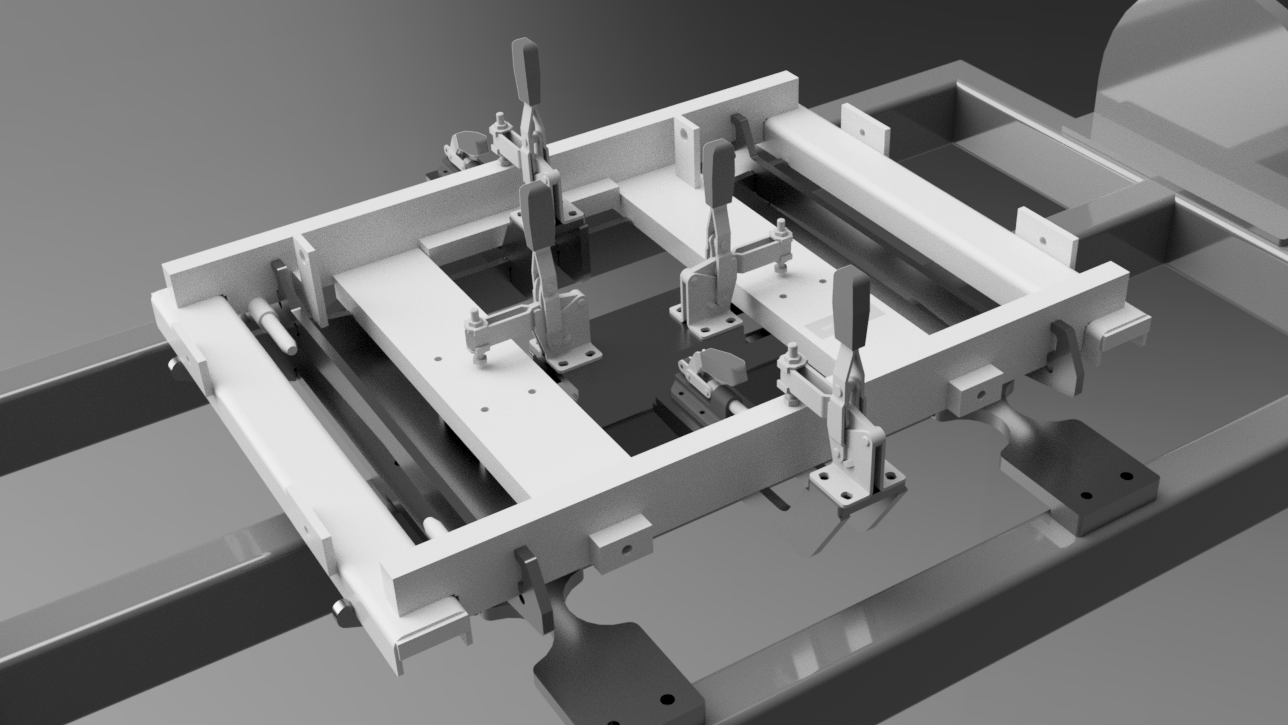

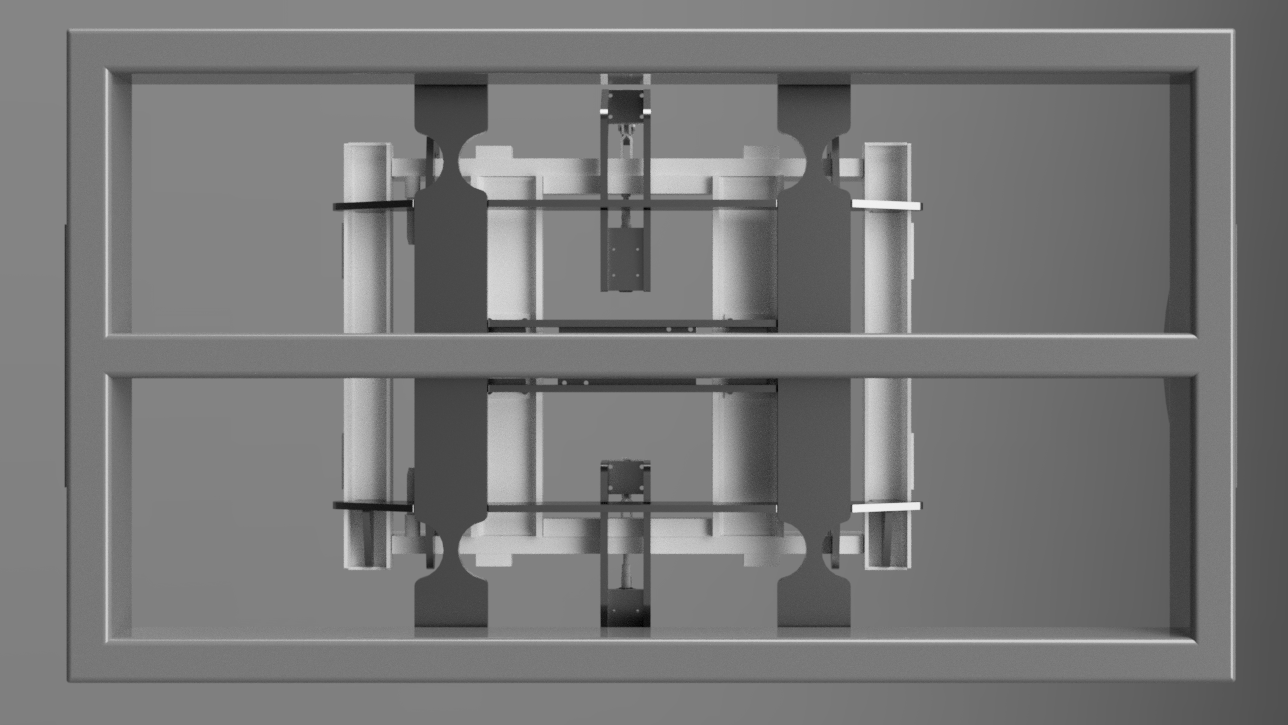

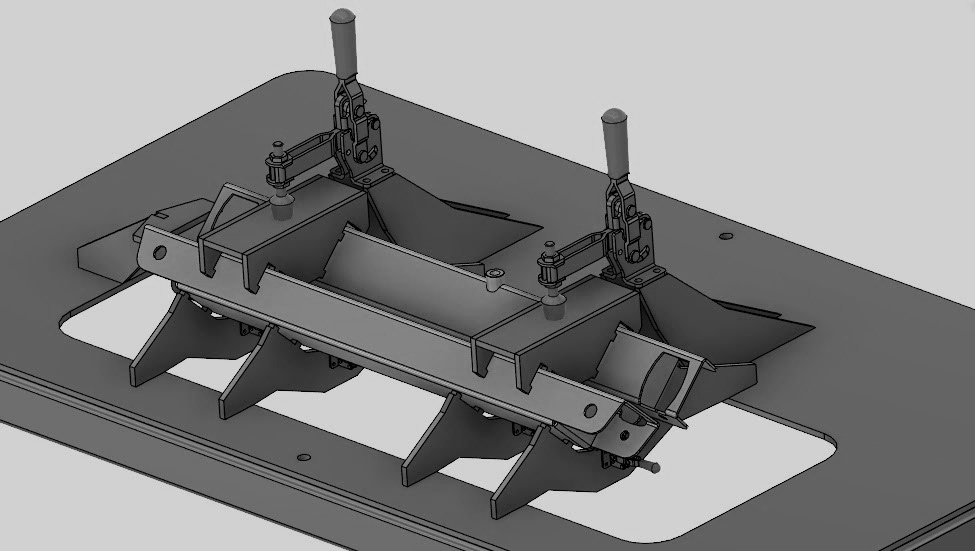

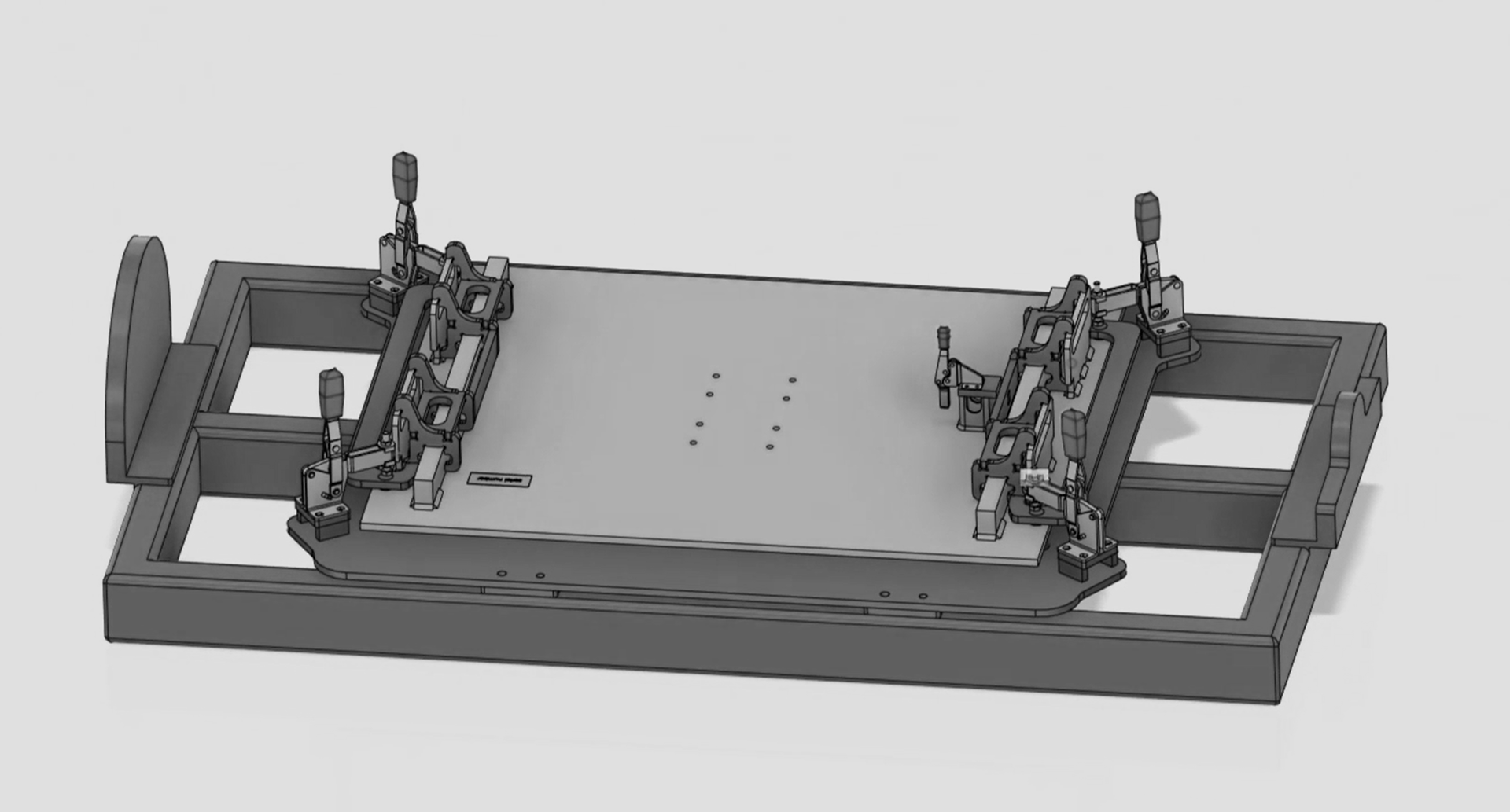

Need a welding jig quickly? We have more than ten years of experience with robot welding and designing welding jigs with a main focus on the user-friendliness for the operator and the efficiency of the production process. You can also contact us for a welding jig to help with hand welding.

For welding with the welding robot, it is extremely important that the product is properly positioned, a well-designed welding jig is an indispensable starting point. The easier the welding jig is to use and maintain, the better, as the operator can easily put the welding jig into use and have little to take into account wear.

The design of a welding jig requires a good understanding of the entire welding process with the robot, the composition to be welded and the desired end result. Using 2D working drawings or a 3D model of the part to be welded, we can design a custom welding jig entirely according to your wishes and within the given time.

We can also take care of the production, welding, assembling, and testing of the fixture to guarantee it meets your high quality production standards.